How Is Cotton Graded? Exploring the Different Grading Criteria

Did you know that 95% of all clothing items in the world are made with cotton? It’s no wonder why this natural fiber is so popular! But how do we make sure that our cotton is of the highest quality? That’s where grading comes in. In this article, we’ll explore the fascinating world of cotton grading and find out exactly what makes one grade of cotton better than another.

As we dive into the world of cotton grading, let’s start by looking at some basic definitions. Cotton is a soft, fluffy staple fiber that grows around seeds in a pod on a flowering plant called Gossypium. The fibers from these plants can be spun into yarns and threads which are then used to create fabrics for clothing.

Grading is an important procedure when it comes to ensuring the quality and consistency of cotton products. Different grades are assigned to individual batches of raw fibers based on their physical characteristics such as length, strength, cleanliness, and color. Each grade is given a specific number which indicates its level of quality and determines its suitability for certain applications. By understanding these grades, we can ensure that our products are made with only the best materials available!

What Is Cotton Grading?

Did you know that cotton is the most important natural fiber crop in the world? It accounts for almost 50% of all fibers used globally! So, what exactly is cotton grading?

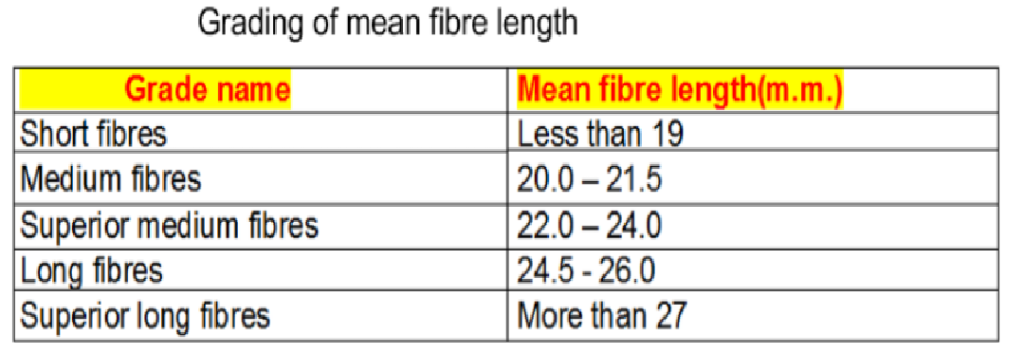

Cotton grading is the process by which certain characteristics of the fiber are assessed and classified. The primary element evaluated during this process is the length of the fibers. Grade standards also take into account other factors such as color, uniformity, strength and maturity. This ensures that only high-quality cotton yarns can be produced from these fibers.

The classification of cotton plays a vital role in determining its market value. The grade assigned to a particular batch of cotton depends on its overall characteristics, which include purity, fineness, length and strength. Cotton grading helps in ensuring the quality of cotton by categorizing it based on these criteria so that buyers are aware of its properties.

Cotton grades are further divided into segments depending on their usage, such as spinning yarns or weaving fabrics. By evaluating these parameters while grading cotton, buyers can identify the best-suited type for their needs and make an informed decision when purchasing this valuable commodity.

Types Of Cotton Grading

Cotton grading is like a game of chess – it requires skill, knowledge and precision. Every move has to be carefully planned in order to achieve the desired outcome. The goal? To produce high-quality cotton with the correct grade symbol and fiber quality. Grading involves classifying cotton according to its length uniformity and other characteristics, such as color, strength, fineness and maturity.

Upland cotton is one of the most commonly used grades of cotton and is typically classified into one of four categories: Low Middling (L/M), Middling (M), High Middling (H/M) or Good Middling (G/M). Each grade has a unique set of requirements that must be met in order for the grade to be certified. For instance, Low Middling must have a length uniformity ratio of at least 2:1 while Good Middling must have a length uniformity ratio of 4:1 or higher.

In addition to length uniformity, other factors such as color, strength and maturity also play an important role in determining the grade symbol for each type of cotton. For example, if the lint color is too dark or too light for its designated grade then it may be assigned a lower grade symbol than what was originally intended. Similarly, if the fibers are not strong enough or too mature then they may not meet the required standards for their designated grade symbol either.

Ultimately, when it comes to grading cotton, precision is key! No matter which type of cotton you’re working with – whether it’s upland or another variety – ensuring that all criteria are met will ensure that you get the best results possible.

History Of Cotton Grading

In the ancient Egyptian civilization, cotton was so valued that it was used to pay taxes. This illustrates the long-standing importance of cotton in our world. But just how is this luxurious fabric graded? Throughout history, the process of grading cotton has been an integral part of the textile industry.

The first grade system for cotton was developed in Egypt and used staple length as its main indicator. Staple length is still a major factor when grading today’s cotton, especially for varieties like Upland Cotton and Egyptian Cotton which are highly prized for their extra-long fibers.

The invention of the Cotton Gin in 1794 revolutionized the way that cotton was processed and made it easier to separate out different grades. This had a huge impact on the global textile industry and paved the way for more efficient methods of grading, sorting, and packaging cotton which are still in use today.

Grading cotton has come a long way since its humble beginnings in Ancient Egypt, but good quality cotton will always remain a highly sought after commodity with an immense value to society.

The Role Of The Cotton Grading System

Admit it, the topic of cotton grading might not sound like the most exciting thing in the world.But don’t worry, we’ll make this interesting! The role of the cotton grading system is an integral part of cotton production and affects how much a farmer can earn from their crop.

Cotton lint, which consists of fibres picked up during harvesting, is graded based on its staple length, fibre maturity, and other factors. This grading system is used to determine the value and quality of a particular batch of cotton. It’s what enables farmers to get a fair price for their hard work.

The grading system also allows producers to differentiate between different types and qualities of cotton, so that buyers can make informed decisions when purchasing raw materials for manufacturing purposes. Cotton lint with higher grades usually fetches higher prices for producers – something that all farmers would be keen to take advantage of!

It’s clear that the role of the cotton grading system is an important one, with implications for both farmers and manufacturers in terms of pricing and quality control. Understanding these factors can help ensure that everyone involved in the cotton production process gets a fair deal.

Factors That Affect Cotton Grading

As fate would have it, cotton is graded according to its quality. To ensure that the product meets the highest standards, a complex classification system is put in place. This system takes into account several factors that affect the cotton’s grading such as quality control, fiber properties, and fiber development. It’s all part of the process to ensure that cottons meet the established standards.

At each step of this intricate grading process, quality control is paramount. The cotton fibers are inspected for their length, luster and uniformity of color and texture. These serve as indicators of their suitability for use in fabric production. The classification system also takes into account other factors such as fineness, strength and maturity of the fibers during development. All these elements play an important role in determining the grade for each batch of cotton.

The grading process is also a reflection of how technology has impacted the industry over time. With modern equipment now available to accurately measure all fiber properties, it has become easier to assess each batch against set standards before being approved for sale on the market. With this improved accuracy in testing and measuring processes, buyers can be sure that they’re getting only high-grade cottons with consistent qualities every single time. That’s why it pays to know what goes into cotton grading so you can make informed decisions when purchasing any type of cotton fabric or clothing item.

It’s clear that thorough evaluations are necessary to ensure quality cottons reach our shelves and homes – but what exactly are the steps involved?

Steps Involved In Cotton Grading

Cotton grading can seem like a complicated task, but when broken down into its individual steps it’s less daunting. To begin, it’s important to understand the factors that affect cotton grading and how they can be used to determine the quality of cotton. Let’s take a look at the steps involved in cotton grading.

The first step in cotton grading is color grade, which is determined by assessing the color of the fibers. This is done with the use of USDA classing equipment to measure the degree of reflectance or light absorption of each fiber. The second step is leaf grade, which involves measuring the length, thickness, and uniformity of cotton fibers. This helps to determine overall fiber strength and yield potential of different cottons. Finally, factors such as micronaire, strength properties, and other characteristics are also taken into account when evaluating cotton quality.

By taking all of these steps into consideration when performing cotton grading, producers can ensure their product meets industry standards and customer expectations for high-quality fiber products. It also provides producers with valuable insights that can help them optimize their processes for better yields and higher profits. By understanding the importance of cotton grading, producers can make sure their business runs smoothly – from harvesting to shipping!

Benefits Of Cotton Grading

Cotton grading has become an essential part of the cotton industry. Here are a few of the benefits that come with it:

- Grading raw cotton helps to separate and classify different types of cotton based on their quality, making it easier for manufacturers to purchase the kind of cotton they need. This way, buyers know exactly what they’re getting, helping them make informed decisions.

- A grade sequence depending on criteria is used to grade cotton and categorize it into different grades. This helps ensure that high-quality raw materials are being used in the production process, resulting in better-quality products.

- With proper grading of raw cotton, buyers can be sure that the material they receive meets their standards and expectations. Additionally, this helps reduce wastage while improving efficiency in production processes.

- By grading cotton correctly, buyers can also take advantage of pricing structures that are based on quality levels. This will help them not only save money but also increase profitability by maximizing the value from the product they buy.

Grading raw cotton is a beneficial practice for all parties involved in its production and supply chain—from farmers and manufacturers to retailers and consumers—as it ensures better quality control at every stage.

Frequently Asked Questions

What Is The Difference Between Cotton Grading And Cotton Classification?

Have you ever wondered what makes one cotton product better than another? What is the difference between cotton grading and cotton classification?

Cotton is a natural fiber that can be found in many forms and grades. Cotton grading is used to determine the quality of the product based on its physical characteristics, such as length, fineness, color, strength and uniformity. Cotton classification assesses the raw material itself and not its processing or durability.

Let’s look at some key differences between grading and classification when it comes to cotton products: • Grading evaluates finished products while classifying looks at raw materials; • Grading focuses on appearance, performance, and durability while Classification considers fiber type and staple length; • Grading takes into account US standards while Classification follows international standards.

So why does this matter? Knowing these distinctions can help you make an informed decision when investing in cotton products. Whether you are looking for a piece of clothing or a bedspread, understanding the differences between grading and classification will ensure you get what you pay for – quality!

How Long Does The Cotton Grading Process Take?

The cotton grading process can take anywhere from a few days to several weeks, depending on the size of the batch being graded and the complexity of the process. For example, if there is a large amount of cotton to be graded, it may take longer to grade than a smaller batch. It also depends on how much detail needs to be considered when grading; some batches may require more intricate analysis than others.

In order to accurately grade cotton, different characteristics are taken into account, such as length and fineness of the fibers. This information is used in combination with an established system for grading cotton which has been developed based on industry standards. The grades range from 1-4 and are judged based on various qualities such as color, maturity of seed, fiber strength, and other factors.

The amount of time that it takes to grade cotton can vary greatly, depending on the size and complexity of the batch being graded. It’s important that all factors are taken into consideration so that an accurate result is achieved as quickly as possible.

TIP: Don’t let time constrict you too much; make sure you take enough time when grading cotton so that it is done correctly and efficiently!

What Is The Cost Of Cotton Grading?

Cotton grading can be a costly process, with the costs ranging depending on the degree of accuracy desired. From the simple to the more intricate, cotton graders must consider their budget before taking on this task.

The cost of cotton grading can vary significantly, depending on how much input is needed. If only a basic grade is required, then the cost may be minimal. However, if an extra detailed analysis is required then prices can quickly add up. Companies that provide these services need to factor in labor costs and other expenses in order to determine their pricing structure.

Fortunately, there are ways to save money when it comes to cotton grading. Working with experienced professionals or shopping around for lower rates can help keep costs down while still obtaining quality results. With careful planning and research, businesses can get accurate grades for their cotton without breaking the bank.

What Impact Does Cotton Grading Have On The Environment?

Cotton grading has a far-reaching impact on the environment. While it’s a necessary measure for quality assurance, it can also have a detrimental effect on our natural resources. Let’s look into how cotton grading affects the environment and what we can do to mitigate its effects.

It may seem like an innocuous process, but the truth is that cotton grading can have serious consequences if not done responsibly. For starters, it consumes large amounts of water, which can be especially problematic in arid regions where water is already scarce. It also uses chemicals such as bleach and dye that can pollute water sources when released into them. In addition to this, cotton grading produces a lot of waste in the form of discarded fibers or parts of garments that are not up to standard.

These issues aside, there are some ways to make sure that cotton grading doesn’t harm the environment too much. Here’s a quick list:

- Use eco-friendly dyes and bleaches instead of chemical-based ones.

- Reuse or recycle any materials that can’t be used for production instead of discarding them.

- Utilize sustainable practices such as rainwater harvesting and wastewater treatment systems wherever possible.

By taking these measures, we can minimize the environmental cost of cotton grading while still ensuring quality products for consumers. After all, it doesn’t have to be one or the other – we can strive for both!

Are There Any Dangers Associated With Cotton Grading?

Cotton grading is an essential process for the production of quality cloth. But it can also be hazardous if not done properly. From chemical hazards to health risks, there are a number of dangers associated with cotton grading that must be taken into consideration.

For starters, the chemical treatments used in cotton grading can cause serious harm to the environment. These materials might include peroxide, chlorine bleach and other solvents which release toxins into the air and water supply. Furthermore, these chemicals can irritate workers’ eyes and skin if proper safety measures aren’t taken.

Not only that, working in a hot and humid environment also poses a risk to workers’ health. Cotton graders often have to stand for long periods of time as they inspect fiber samples and this can take its toll on their bodies over time. In addition, they may need to lift heavy bales of cotton which can lead to muscle strain or back injuries if proper lifting techniques aren’t followed.

Therefore, it’s important for employers to take all potential hazards into account when setting up a grading system for their business. This means providing necessary safety gear such as goggles, gloves and masks as well as implementing strict safety regulations so workers are aware of how to stay safe while performing their duties.

Conclusion

In conclusion, cotton grading is an important process that determines the value of cotton. It takes time and money to grade and classify cotton, but it is worth it in the long run for farmers and manufacturers alike. Cotton grading also has a positive impact on the environment by ensuring that only quality fiber is used in production.

However, there are some risks associated with the grading process. For example, a case study from India has shown that improper use of pesticides during cotton cultivation can lead to contamination of the soil, water and air. This can have serious health implications not just for people living near fields where cotton is grown but also for those who handle the graded fibers.

Overall, it’s evident that understanding the importance of proper grading techniques is essential for anyone involved in the production or sale of cotton. By investing in high-quality equipment and adhering to strict safety protocols, we can ensure that our planet remains safe and our industry remains sustainable.